Medical Gas Pipeline System

|

| Medical Gas Pipelines |

Medical Gas Pipelines are used to supply nonflammable gases |( oxygen, nitrous oxide, medical air, etc.) from a central manifold to color-coded pipeline distribution network, which gets terminated in non-interchangeable sockets ( diss) non interchangeable threads or non-changeable quick couplers present in the wall outlets , ceiling pendants, bed head panels etc.

|

| medical gas pipelines |

ideally, appropriate markings of pipes should be done ( at least 20 feet and once in every room .)and flow of gas should be displayed .

GENERAL RULE OF KEEPING AWAY PIPELINE from :

- MECHANICAL DAMAGE

- CHEMICAL DAMAGE

- EXCESSIVE HEAT

- ELECTRICAL SPARKS

There are 3 component in medical gas pipeline .

- SOURCES

- DISTRIBUTION SYSTEM

- OUTLETS

SOURCES:

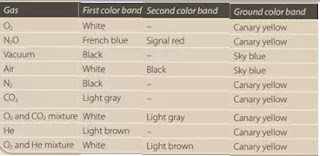

Oxygen is supplied from oxygen cylinder manifold or VIE . and color coding of oxygen pipeline is white ..

Medical air is supplied from cylinder manifold or compressor. and color coding of medical air pipeline is black .

Nitrous oxide is supplied from nitrous oxide cylinder manifold and colour coding of nitrous oxide pipeline is french blue .

|

| color code of medical gas pipeline |

|

| color code of medical gas pipeline |

DISTRIBUTION SYSTEM :

There are generally 3 classes of pipeline

|

| Medical Gas Pipeline System |

- Main pipeline

- Risers

- Branch lines (lateral)

1. The main pipeline.

They connect two sources to risers or Branch lines or both.

2. Risers.

3. Branch lines. Also known as literal lines.

Distribution system. Consists of a shutoff valve

Classification of shut-off valves.

A. Service shutoff valves:

B. Manual/Zone shutoff valves in boxes with fixed covers or doors.

Pressure relief valve. Pressure relief valve.

Master alarm system is used to monitor.

The central gas supply of all Central Medical gas supply of all the gases at one place. It is the central part central control room from where monitoring. Is done and is responsible for the smooth and continuous supply of medical gas.

Area alarm system.

Local alarm.

Terminal units

Base block.

Primary valve

Secondary valve.

Gas-specific Connection Point

OUTLETS

- Fall Outlets

- . Ceiling-mounted horses.

- Ceiling pendants.

- Ceiling columns.

- Horizontal Bed. Head panels.

- Flexible horses flexible Pipelines.

- Oxygen flow meter with humidifier.

|

| diss system |

Recommended Topics

Label List

- BASIC CONCEPTS (19)

- ANESTHESIA EQUIPMENTS (18)

- Exam (13)

- study material (12)

- MCQ FOR OT TECHNICIANS (11)

- ANESTHESIA PREPRATION (10)

- DEVICES USED IN OT (7)

- random topics (7)

- CSSD & OTHER DEVICES (6)

- FIND A JOB (5)

- QUESTION PAPERS (5)

- latest updates (4)

- DRUGS (3)

- PATIENT CARE (3)

- Registration (3)

- Surgical Instruments (3)

- History of Anesthesia (2)

- by - Ritika Sharma (1)

Post a Comment

Post a Comment